Page 50 - 20250602 EEA QM Edition 6.0

P. 50

Quality Requirements Edition 6.0 European Enamel Association

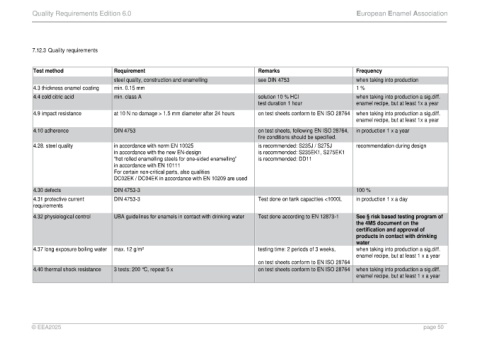

7.12.3 Quality requirements

Test method Requirement Remarks Frequency

steel quality, construction and enamelling see DIN 4753 when taking into production

4.3 thickness enamel coating min. 0.15 mm 1 %

4.4 cold citric acid min. class A solution 10 % HCl when taking into production a sig.diff.

test duration 1 hour enamel recipe, but at least 1x a year

4.9 impact resistance at 10 N no damage > 1.5 mm diameter after 24 hours on test sheets conform to EN ISO 28764 when taking into production a sig.diff.

enamel recipe, but at least 1x a year

4.10 adherence DIN 4753 on test sheets, following EN ISO 28764, in production 1 x a year

fire conditions should be specified.

4.28. steel quality in accordance with norm EN 10025 is recommended: S235J / S275J recommendation during design

in accordance with the new EN-design is recommended: S235EK1, S275EK1

“hot rolled enamelling steels for one-sided enamelling” is recommended: DD11

in accordance with EN 10111

For certain non-critical parts, also qualities

DC02EK / DC04EK in accordance with EN 10209 are used

4.30 defects DIN 4753-3 100 %

4.31 protective current DIN 4753-3 Test done on tank capacities <1000L in production 1 x a day

requirements

4.32 physiological control UBA guidelines for enamels in contact with drinking water Test done according to EN 12873-1 See § risk based testing program of

the 4MS document on the

certification and approval of

products in contact with drinking

water

4.37 long exposure boiling water max. 12 g/m² testing time: 2 periods of 3 weeks, when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

on test sheets conform to EN ISO 28764

4.40 thermal shock resistance 3 tests: 200 °C, repeat 5 x on test sheets conform to EN ISO 28764 when taking into production a sig.diff.

enamel recipe, but at least 1 x a year

© EEA2025 page 50